Scs-10k For Cooling Tower

SCS-10K is a highly effective, safe, quick and broad spectrum disinfectant, recommended to the world by WHO and FAO with class A1. It is the fourth generation of disinfectant after Bleaching Powder (Pypocholoride), Sodium Dichloroisocyanurate (SDIC (sodium dichloroisocyanurate)) and Trichloroisocyanuric Acid (TCCA). SCS- 10K is a good sterilization agent against bacteria, mold, fungi, virus, as well as their spores.

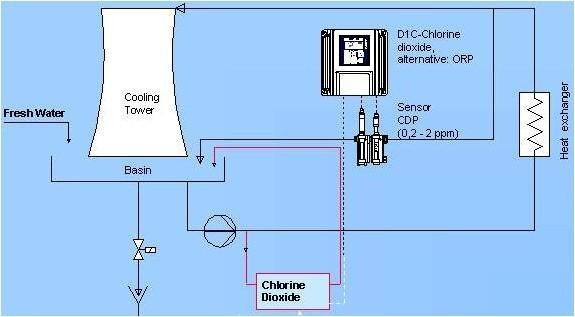

Due to high temperatures and permanent scrubbing of nutrients, cooling towers shape a perfect environment in which microorganisms can thrive. The circumstances in cooling towers are ideal for the growth of Legionella bacteria. Controlling and preventing the growth of microorganisms in a cooling tower system is extremely important for health reasons and required to keep the system running under optimal operating conditions. The presence of the microorganisms may cause the system to breakdown, decrease the efficiency of the heat transfer and hence need to be replaced more rapidly.

Microorganisms may cause serious problems in the system through which the cooling water circulates:

- Buildup of odor episodes and slimes caused by an

- Increased microorganism population

- Loss of heat transfer, due to the low thermal conductivity of the biofilm and inorganic deposition;

- Increased corrosion rates, due to electrochemical cell formation in the biofilm and blocking of contact of any corrosion inhibitor with the metal

- Increased pumping energy required to circulate the cooling water in the presence of a biofilm which has a high friction factor.

- Lack of microbiological control the water circuit may impose unacceptable health risks, such as the formation of Legionella species, which in turn may lead to an outbreak of Legion- naires' disease, a frequently fatal form of pneumonia

For total cooling tower treatment, a variety of chemicals is available which are typically applied as a cocktail. These chemicals have specific characteristics that individually address respective chemical and microbiological needs in the water circuit of the cooling tower. Most commonly used chemicals in the cocktail are scale and corrosion inhibitors, biocides, algaecides, slimicides, bio-dispersants and pH regulators. The most ideal solution would be to employ a biocide that incorporates all these chemicals in one product for cooling water treatment. Typically oxidizing biocides such as chlorine and bromine or non-oxidizing compounds like glutaraldehydes have been used to treat cooling tower water. Unfortunately, these chemicals are highly reactive with other chemicals and organics present in the water. Once these reactions take place, these biocides lose much of their ability to eliminate the microorganisms present.

Contrary to chlorine, SCS-10K is very non-reactive to other items found in the water and fully retains its biocidal efficacy. Likewise it is also a superior biocide for removing the biological film layers' "slime layers" found within the cooling tower system. It is the formation of theses biological film layers that lead to the most predominant challenges that all cooling towers face.