Packer Screen (ODEX & DTH)

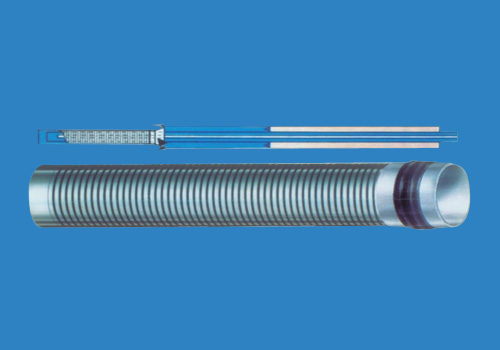

The well, after drilling by odex method upto the target depth of 90 meters the casing needs to be Jacked up to about 11 feet or more of bottom depending on the water bearing strata. The drilled hole (naked portion below casing shoe) may be checked for clearance upto the depth of the well. In case it is found clear upto the bottom, Bharti Packer Screen of dia. 3" / 4" dia. having a length of 2 to 6 meter long as per requirement, blind at bottom and ring type self sealing packer (single element - K Packer) welded on to the top of the screen is dropped into the 128 mm casing. The screen is allowed to go inside the casing by its on weight and will land just above the casing shoe ( Internal dia. meter of the casing shoe is less then the ID of the casing).

In case it is not feasible to jack the casing, which is known during, the time of drilling, the drilling by Odex method should be stopped above the targeted depth depending upon the water bearing strata. The Odex unit is retracted and pulled out of the hole. A suitable conventional bit is run to drill below the casing shoe using "DRILLING FOAM OIL".

It has to be ensured that during naked hole drilling the hole is stable as and when the string is lowered back to the depth drilled the free string indicates the hole is clear After drilling 11 feet or more depending upon the condition of the hole the Bharti Packer Screen 3" 4" Dia, blinded at the bottom and self-sealing packer (single element K-Packer) welded at the top of the Bharti screen is dropped inside of the 128-mm casing and allowed to go upto casing shoe by its on weight.

In case of doubt about landing of the Bharti Screen upto the top of the casing shoe drilled pipe attached to 4" Dia. blind peace can be run in the hole when this touched the packer gently further lowering will push Bharti Screen Packer system inside the casing and stop at the top of the casing shoe. The well should be developed with the air compressor for one to two hour maximums this well result in a naturally packed well. The screen opening (slot size) may be selected as per the strata encountered.

A well has been constructed by The Central Ground Water Board using Bharti Screen in boulder formation (Glacial Bolder) at Ladakh and the zones tapped were glacial boulders. Drilling had to be done by Odex method and the casing could not be lifted therefore blind drilling for 11 ft was done and Bharti screen of 4" Dia. with self-sealing packer (single element K Packer) welded onto the screen was dropped inside the 128-mm casing, which landed write at the top of the casing shoe. This parrticular well for Mahabodhi International Meditation Center Leh Ladakh was clear willing when developed with air 'compressor yielded 4-5 lps continuous discharge where other near by wells giving yielded only 1 LPS in which no screen was used

It is feasible to tap a greater length of water bearing strata while using Bharti screen. Since the cost of the drilling and casing pipe remain same, the extra cost is due to use of Bharti screen and packer, is quiet negligible as compared to the benefit of yield i.e. 4 to 5 times more. It is clear that instead of a hand pump a submersible pump was lowered because of more yields from the completed well using Bharti screen. The well is running satisfactorily giving sand free discharge.

Various advantage to use Packer Screen in Hard Rock / Boulder Areas

- In case no screen is used it is as good as a cavity well in which very small section of the strata is tapped and the chances of its earlier failure cannot be ruled out

- In case after boulders the producing strata are sand the screen will be added advantage to control the sand production

- In hard rock area also the sand and chips in the fractures will chock the well. In case screen is used the cutting will not enter the well and pump will not be damaged in filling will not be there thus life of the well is also increased

- By using screen a larger section of the strata can be tapped when the fixed capital cost remain same like drilling charges, Casing Pipe etc.

- Due to opening area to the extent of 3 to 4 times more than the vertical slot pipe is the draw down will be reduced resulting in lowered pump running cost

- Without use of Bharti Screen more number of wells have to be drilled in the same location and that to without higher yield per well

- In case the well is to be decommissioned, the screen can be extracted for use in the next well